[ad_1]

A brass annealing machine is a as soon as elite piece of reloading gear that has change into extra mainstream not too long ago. Although I’ve reloaded for greater than 20 years, I’ve been largely only a purposeful reloader and hadn’t even heard of annealing till just a few years in the past. I nonetheless don’t have all the very best and newest gear, and far of my reloading work is for searching, however as my quantity of capturing and reloading has grown, I’ve determined that annealing is a clever selection to enhance the consistency and repair lifetime of my brass. There are a variety of choices in the marketplace, however when looking for a brass annealing machine for myself, the Ugly Annealer from Derraco Engineering caught my eye — right here’s what I consider it after annealing 5,000 items of brass with it.

The Ugly Annealer Specs

- Dimensions: 10.5 inches X 6 inches X 13.5 inches

- Stainless Metal Housing

- Annealing kind: Gasoline (propane)

- Diamond-grit-coated rotation wheels (2)

- Cartridge compatibility: .223 Rem. to .50 BMG

- Worth: $271

Key Options

- Massive case hopper with detachable retention plate

- Exactly adjustable voltage/velocity

- Extra rotation wheel included

- Contains 5 cartridge inserts

Evaluation Highlights

- Easy and simple to assemble and repair

- Diamond grit wheel coating shouldn’t put on out and spins circumstances reliably

- Massive hopper holds round 170 .308/6.5 CM circumstances, and round 260 .223 Rem. circumstances

- Principally hands-off operation as soon as working

What Is Annealing and Why Does It Matter to Reloaders?

Annealing is a heat-treating course of through which supplies are heated above their recrystallization temperatures, then allowed to chill in an effort to make them extra ductile (much less brittle). Many metals are annealed in order that they are often labored, stamped, or rolled with out breaking. For rifle brass, this implies heating the case (normally the neck and shoulder) to make it extra malleable after firing. It’s frequent for producers to anneal, although a few of them clear the brass to take away the annealing discoloration. In case you’ve seen cartridges with darkened brass across the shoulders and necks, that’s from annealing.

Every time we fireplace a case, the grain construction of the brass will get barely extra brittle. We fireplace, re-size, and fireplace once more till ultimately the case neck cracks. As a bit of metallic is labored, it steadily hardens, then ultimately cracks. Annealing successfully resets the grain construction to a extra ductile state.

For the shooter and reloader, annealing after each firing could make your brass last more and supply higher neck pressure consistency. Neck pressure describes how firmly the case neck holds onto the bullet, and if that’s extra constant, likelihood is that your accuracy can be extra constant too.

Not each reloader wants to fret about annealing, but it surely’s a wonderful solution to get essentially the most out of your elements — particularly premium brass. When you’ve got a tough time preserving monitor of what number of occasions your brass has been fired or, like me, have a five-gallon bucket of brass with combined numbers of firings, annealing might help enhance the consistency of that too.

Flame Annealing Vs. Induction Annealing

There are a variety of various methods to anneal brass. Earlier than you would simply purchase a brass annealing machine, shooters developed alternative ways to do it. Usually although, brass is annealed with a propane gasoline flame or by a brass annealing machine that makes use of induction (an electromagnetic subject) to use the warmth. Induction annealing is theoretically extra exact and constant, and among the best brass annealing machines you would purchase is an AMP Mk II for round $1,700 (after they’re in inventory).

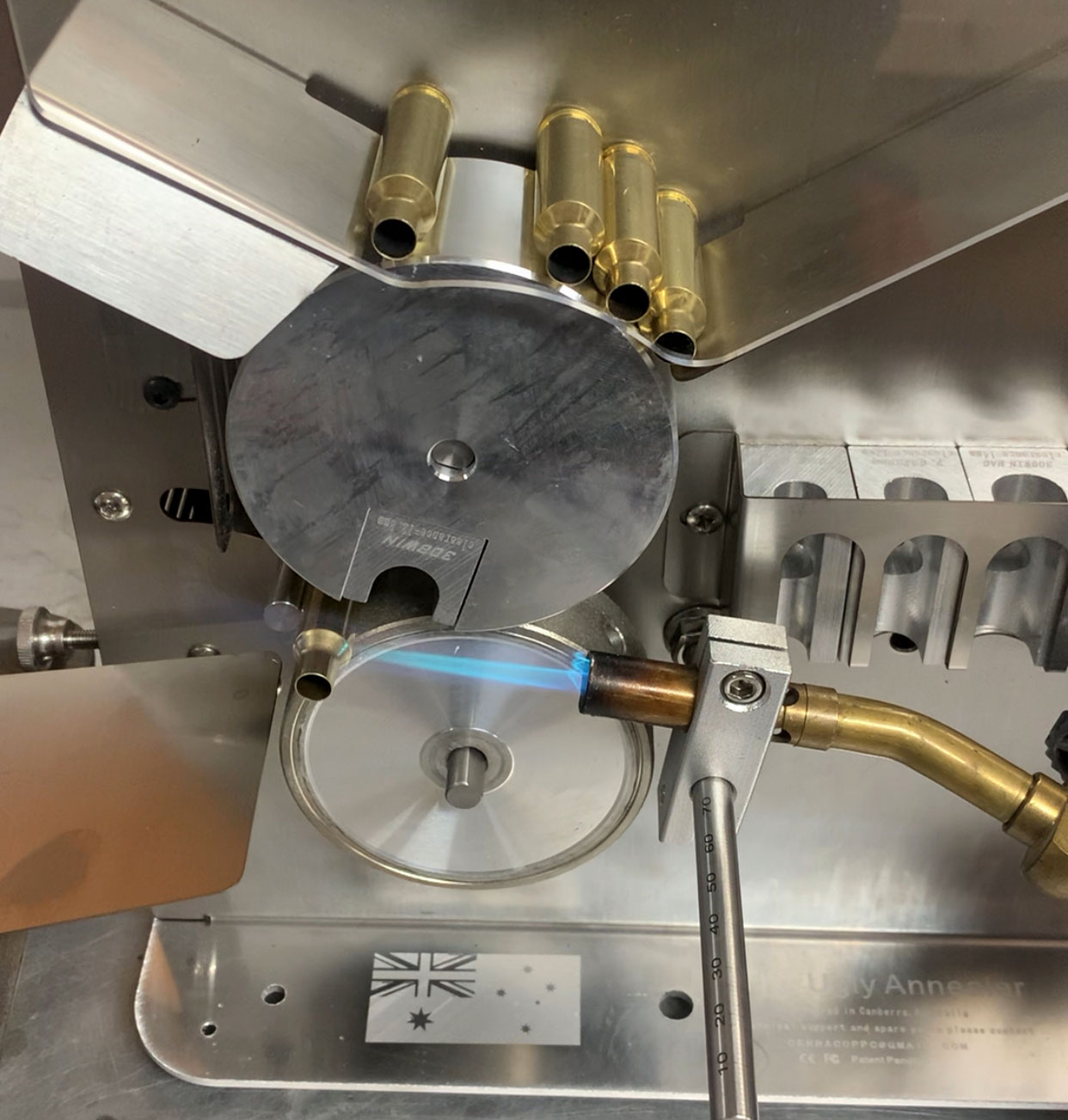

For many shooters, a gasoline flame annealer is a extra sensible and efficient selection. There’s some selection, however these machines typically rotate one piece of brass at a time by way of one or two propane flames till the correct temperature has been reached. That’s normally between 500 and 800 levels Fahrenheit however the normal consensus is that 700 or 750 levels is acceptable. Every brass alloy requires a barely completely different temperature, and I get the impression that flame annealing isn’t an actual science. The flame place, publicity time, case lot, caliber, and gasoline regulation all play an element, so most folk goal for the very best consistency they’ll get. It’s frequent to make use of a temperature-indicating lacquer like Tempilaq contained in the case neck to tune within the correct flame and publicity time.

Why I Selected The Ugly Annealer

Selecting a brass annealing machine to purchase felt just a little redundant, as lots of them are functionally comparable and price about the identical. There are some horizontal rotating plate annealers like these from AGS, however I wished one of many dual-wheel, vertically oriented fashions just like the Annealeez or Burstfire. Nonetheless, when searching choices on Amazon, I got here throughout the Ugly Annealer. At first look, it gave the impression to be just about the identical because the earlier two, however with a bigger hopper. What grabbed my consideration was that the Ugly Annealer had fivefold the variety of constructive evaluations that any of the others had, with a be aware from Amazon that the majority prospects preserve this merchandise. I take all that with a grain of salt, but it surely appeared to offer a greater function set at an identical value, so I ordered one.

The Ugly Annealer Brass Annealing Machine: Set-up and Operation

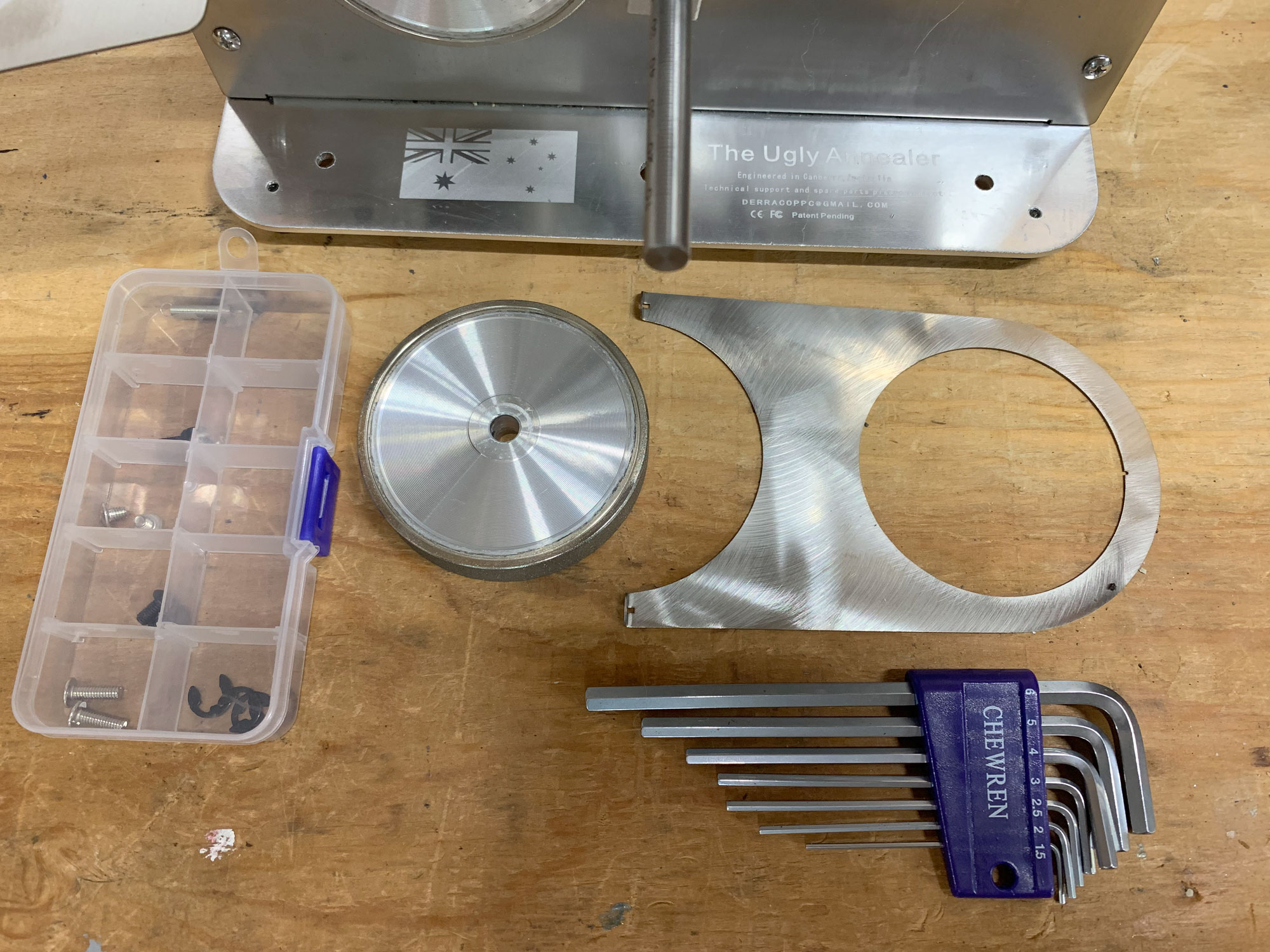

The Ugly Annealer is an easy machine and requires minimal meeting. It additionally comes with an Allen key set and extra small screws and components. The bottom plate and housing are stainless-steel, and the rotating wheels and cartridge case blocks are aluminum. With the bottom, entrance information panel rod, and gasoline torch clamp put in, you’re able to arrange on your favourite cartridge.

One factor I like concerning the Ugly Annealer is that it’s simply adjustable to accommodate nearly any cartridge. The unit comes with 5 completely different sized inserts for the brass catching wheel to accommodate something between .223 Rem. and .50 BMG. Much less frequent, a .22 or .17 Hornet insert will be bought individually. The inserts are held into the brass catching wheel by a single machine screw and have a machined trough into which a single casing can drop because the wheel rotates beneath the hopper. The hopper entrance information panel is evident polycarbonate and the depth is adjustable to permit for shorter or longer circumstances.

The Ugly Annealer comes with an AC energy twine that plugs into the highest of the unit subsequent to the on/off toggle button. The one management on the unit is the voltage regulation knob which adjusts the velocity of the motor and consequently, the publicity time every case has within the flame. Additionally on the highest is a digital setting indicator show that’s helpful to make use of as a reference when fine-tuning publicity time.

Primary Operation

The Ugly Annealer is straightforward to function. After preliminary setup, you’ll wish to high quality tune your velocity and flame. Set just a few casings within the hopper, arrange your propane torch (the package additionally features a bottle stand for non-standard torches), and switch the unit on. The brass catching wheel will pull a case from the hopper and drop it on prime of the brass rotation wheel (which is adjustable for depth, and a thinner wheel is included for brief cartridges), and the diamond-grit-coated wheel spins the case within the flame. Because the brass catching wheel is about to drop one other casing onto the rotation wheel on the finish of the cycle, the adjustable ejection bar pulls again, permitting the annealed casing to slip off into your assortment container.

When you get the correct settings established, flip the machine off, stack your circumstances within the hopper, flip it again on, and let it work.

Utilizing the Ugly Annealer

Time will inform for longevity, however the Ugly Annealer seems to be well-built with good supplies, and must be user-serviceable if something does break. After shopping for mine, I annealed roughly 5,000 items of brass to check it. That included .223 Rem., 6mm Creedmoor, 6.5mm Creedmoor, .308 Win., .30/06, .270 Win., 7mm PRC, .300 Win. Magazine., and .300 H&H Magazine.

I might simply re-fit the Ugly Annealer for various cartridge circumstances. Actually, it normally took longer to get the velocity setting for various circumstances dialed in than it did to make the mechanical changes. The big hopper would maintain roughly 170 items of 6.5 Creedmoor, .308, or .30/06 brass, and round 260 items of .223. Principally, it was a set-it-and-forget-it machine. You wish to fastidiously monitor it, however you’ll hardly ever should make changes as soon as it will get going — particularly with bigger circumstances. The one hiccup I had was when annealing .223 with a fully-loaded hopper. There’s a small lip on the brass catching wheel that catches on the .223 brass and below the load of the loaded hopper. It did bind up as soon as and I needed to unload the hopper. I annealed brass just about continuous for a number of days, and I’m fairly happy.

Issues I Actually Like About The Ugly Annealer Brass Annealing Machine

- I actually just like the simplicity and adjustability of this annealer. It’s not constructed to look good, however constructed to final. There’s nothing shoddy about it.

- The big hopper and detachable entrance information panel are fairly helpful when you’re annealing a big amount of brass. With out the information panel, brass can simply get bumped out.

- The caliber conversion blocks present a great match for all kinds of cartridges.

- The diamond-coated brass rotation wheels spin the brass very persistently — a grievance I hear about different fashions with rubber-coated wheels is that the rubber typically slips and gained’t spin the case.

Issues I Want Have been Higher On The Ugly Annealer Brass Annealing Machine

- I believe the one factor I discovered annoying was that the gasoline torch clamp is hard to lock into place with out shifting the flame. I normally left it considerably unfastened, and manually positioned the flame in the beginning of every annealing session, being cautious to not bump the desk.

Brass Annealing Machine FAQ

No, it’s not a requirement. Nonetheless, it will possibly make your brass final for much longer and offer you higher consistency in your reloads.

Most shooters goal for 700 or 750 levels Fahrenheit, however actual temperature varies relying on circumstances and the precise alloy.

Annealing resets and softens the crystal construction of the rifle brass after firing, stopping it from turning into brittle.

Sure, annealing will lengthen brass life when correctly accomplished as a result of it permits extra working cycles earlier than the case neck cracks.

Learn Subsequent: Rifle Nodes: How You’ve Been Losing Your Time and Cash on Load Growth

Last Ideas on the Ugly Annealer

Although an induction annealer just like the AMP might be higher, most shooters will discover the Ugly Annealer to be an ideal worth. It provides an ideal function set that’s superior to comparable aggressive fashions — at about the identical value. It’s straightforward sufficient to arrange and use for small batches of pricey brass. But it surely’s additionally able to dealing with lots of of items of brass with out stopping. It’s not too usually to search out actual gems on locations like Amazon, however I’m glad I purchased the Ugly Annealer.

[ad_2]