The longer the trip distance or larger the general biking quantity, the extra crucial the touchpoints on a bicycle are. Gender, physique dimensions and form, rider flexibility, particular using postures, and different extremely particular person elements make having the proper match on the handlebars, pedals, and saddle troublesome. Throw in private choice, and the optimum match looks like a minuscule goal.

Of the three contact factors on the bicycle, the seat is essentially the most problematic for many. Saddles have improved tremendously within the 4 many years I’ve been spinning pedals. The now-common cutout in the course of the seat was an unlimited enchancment, as was the current transfer to 3D-printed padding.

In the present day, Fizik broadcasts what may very well be the following important development in saddle consolation. The Italian model launches the One-to-One program, which makes use of strain mapping to create a real bespoke {custom} saddle.

How fizik One-to-One Works

The fizik One-to-One course of begins at a choose dealership. The bike owner is given a customized measurement session to find out which of the eight fizik Adaptive saddles is essentially the most appropriate. This choice is based on the general saddle form.

The subsequent step might be essentially the most essential. A strain mapping session that measures 64 saddle touchpoints on the present saddle and the chosen Adaptive saddle identifies peak strain hotspots, instabilities, and asymmetries whereas pedaling.

The fitter measures these parameters with completely different using positions primarily based on the biking self-discipline. For instance, for street bikes, measurements are taken with arms on the tops, brake hoods, and drops.

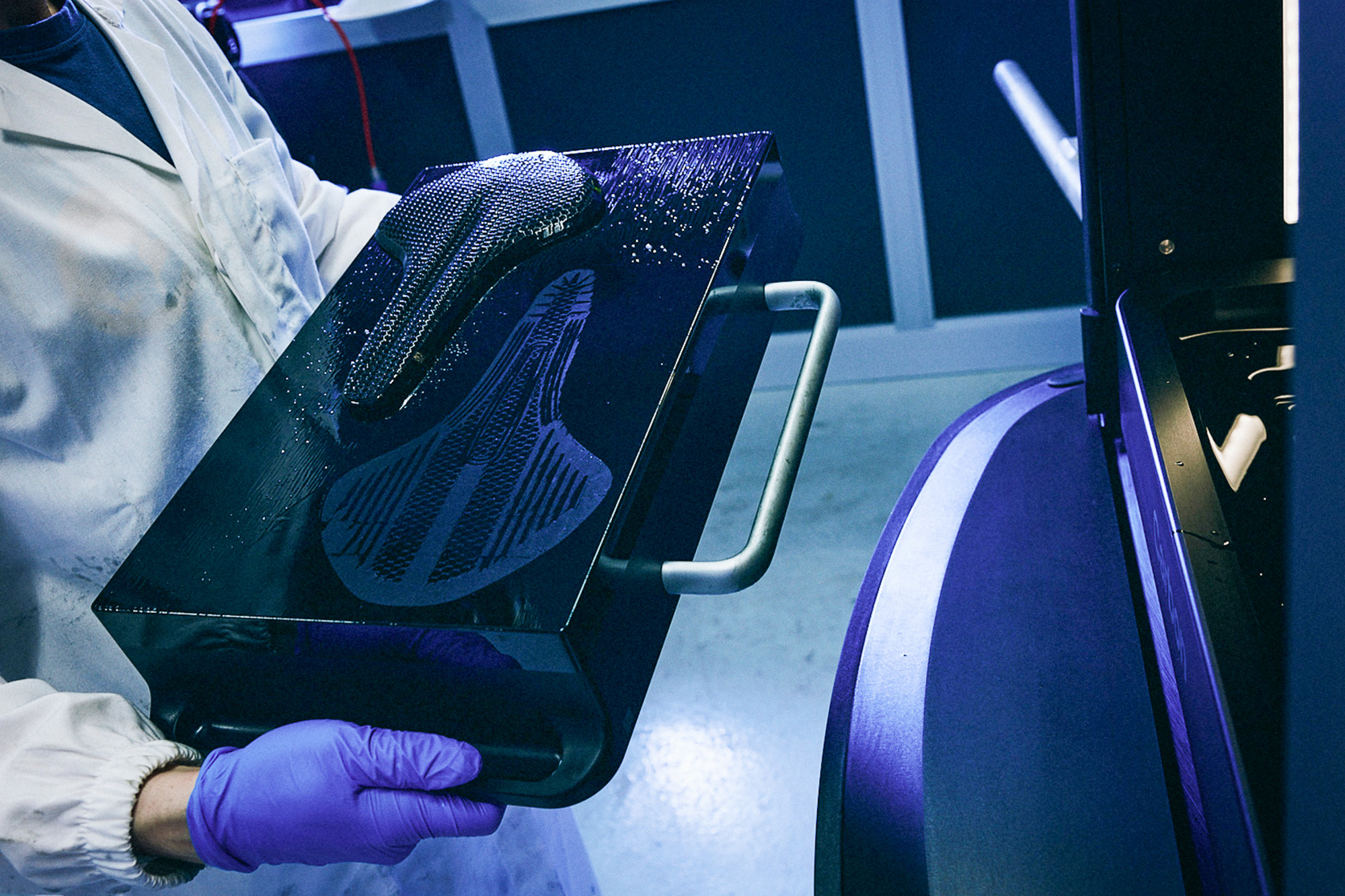

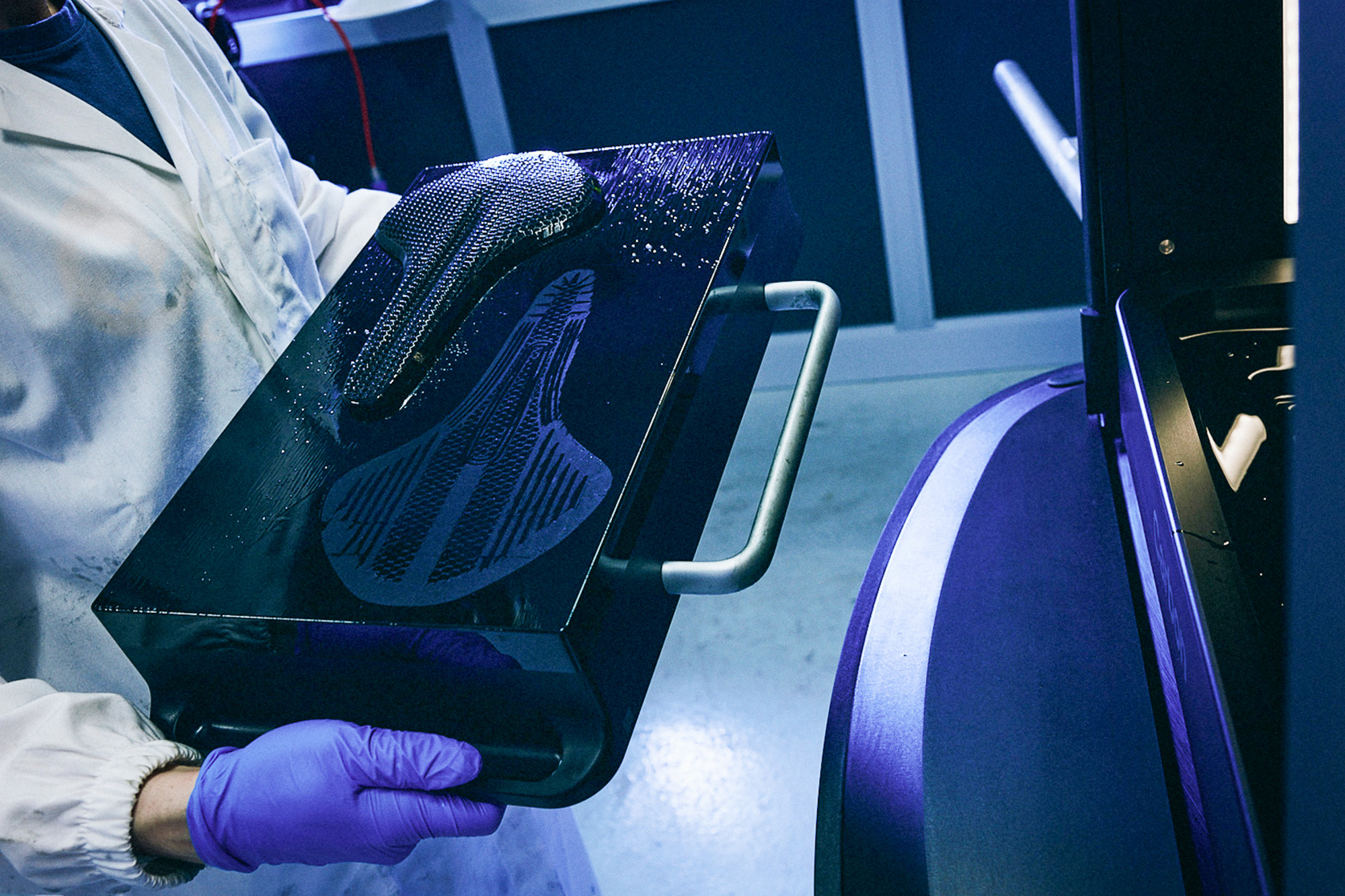

The strain mapping is completed by way of a gebioMized saddle cowl that homes sensors that report this knowledge to a pc. This know-how can also be utilized by very high-end bike becoming providers.

This knowledge is captured and analyzed, and a really {custom}, one-off 3D padding construction is designed to match the bike owner’s wants, as decided by the strain mapping. The shopper then chooses the saddle rail materials they need (carbon or Kium), and the order is distributed to fizik’s headquarters in northern Italy. As soon as the bespoke saddle is constructed, it’s despatched on to the client.

The shopper returns to the fizik vendor for an additional session to file strain knowledge once more. This remaining step highlights the improved measurement parameters. The fizik One-to-One just isn’t the first custom-printed saddle, however it’s among the many first to make the most of strain mapping.

How Do I Get One?

Step one is to find out the closest fizik vendor that provides the One-to-One program; check with this listing. The choose vendor will execute the method from there, and in roughly 2 weeks, your {custom} 3D-printed saddle ought to arrive in your doorstep. After mounting, all that’s left is to return to the vendor for the ultimate strain mapping session.

After all, one thing like this isn’t low cost. fizik One-to-One Adaptive saddles begin at an MSRP of $499. However, needless to say some off-the-shelf fizik saddles have an MSRP of $400. Sure, that’s some huge cash, regardless. However the saddle on a bicycle is a large contributor to general consolation and pleasure, and also you’ve exhausted each different choice. then this can be an answer. And saddles are inclined to final a very long time.

The Way forward for 3D Printing in Biking

I’ve been on inventory 3D-printed saddles for just a few years now, and I’ve to completely admit that they’re super-comfortable and supportive on the similar time. The flexibility to modulate the span from pillowy cushioning to agency help through 3D printing overcomes most of the limitations of froth in basic saddle manufacturing.

I predict 3D printing will improve the opposite touchpoints on a bicycle. The shoe/pedal interface and the glove/handlebar juncture are locations the place I can see 3D printing know-how enhancing each consolation and help. And certainly, I not too long ago obtained discover of 3D printed handlebar tape.

Bicycles have all the time been a platform for manufacturers to flex their technological chops. Most of it’s centered on making the rider quicker. And at instances, these efforts sacrifice consolation for velocity. However fizik One-to-One is refreshing because it’s aimed squarely at enhancing consolation and pleasure. Which, ultimately, could enhance velocity.